MAGS is the new battery-operated electro-permanent magnetic lifter for handling ferrous loads in Industry 4.0 environment.

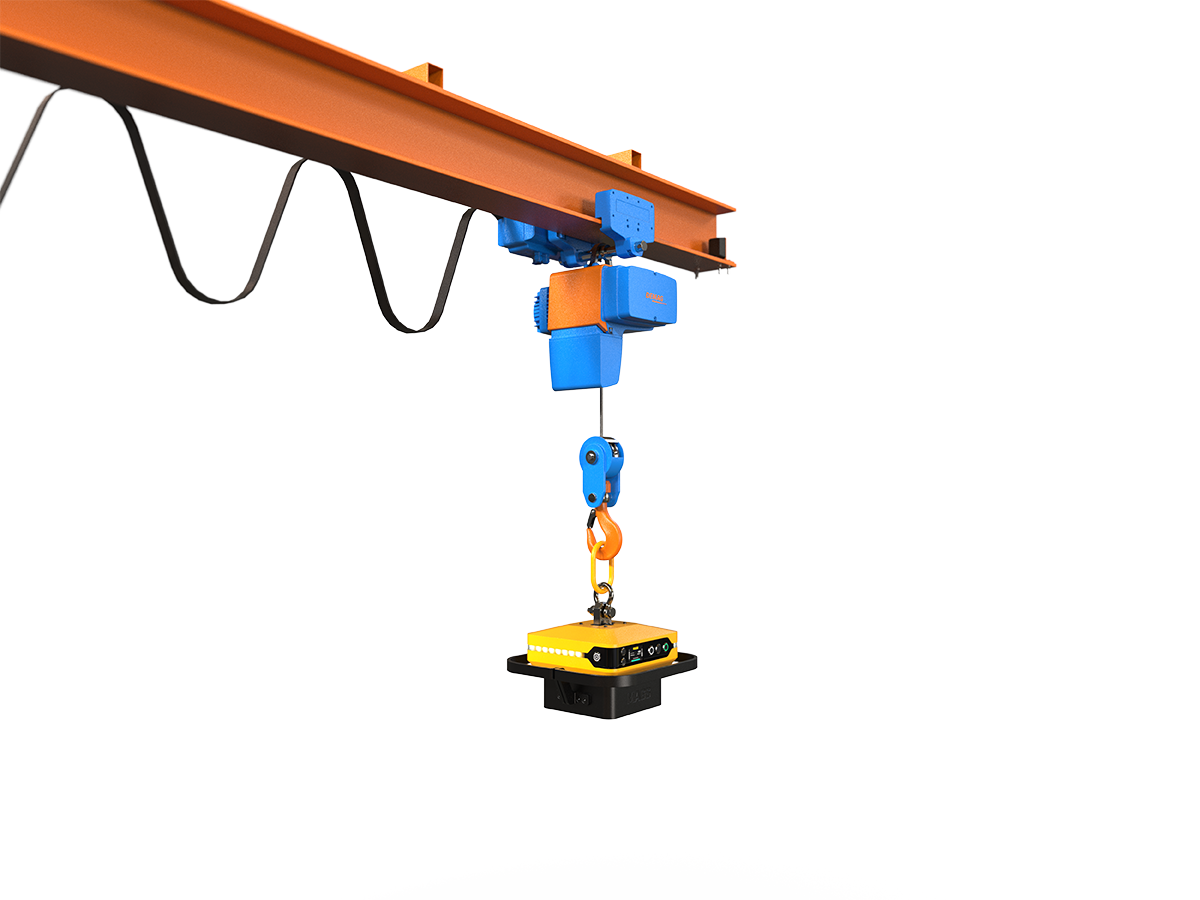

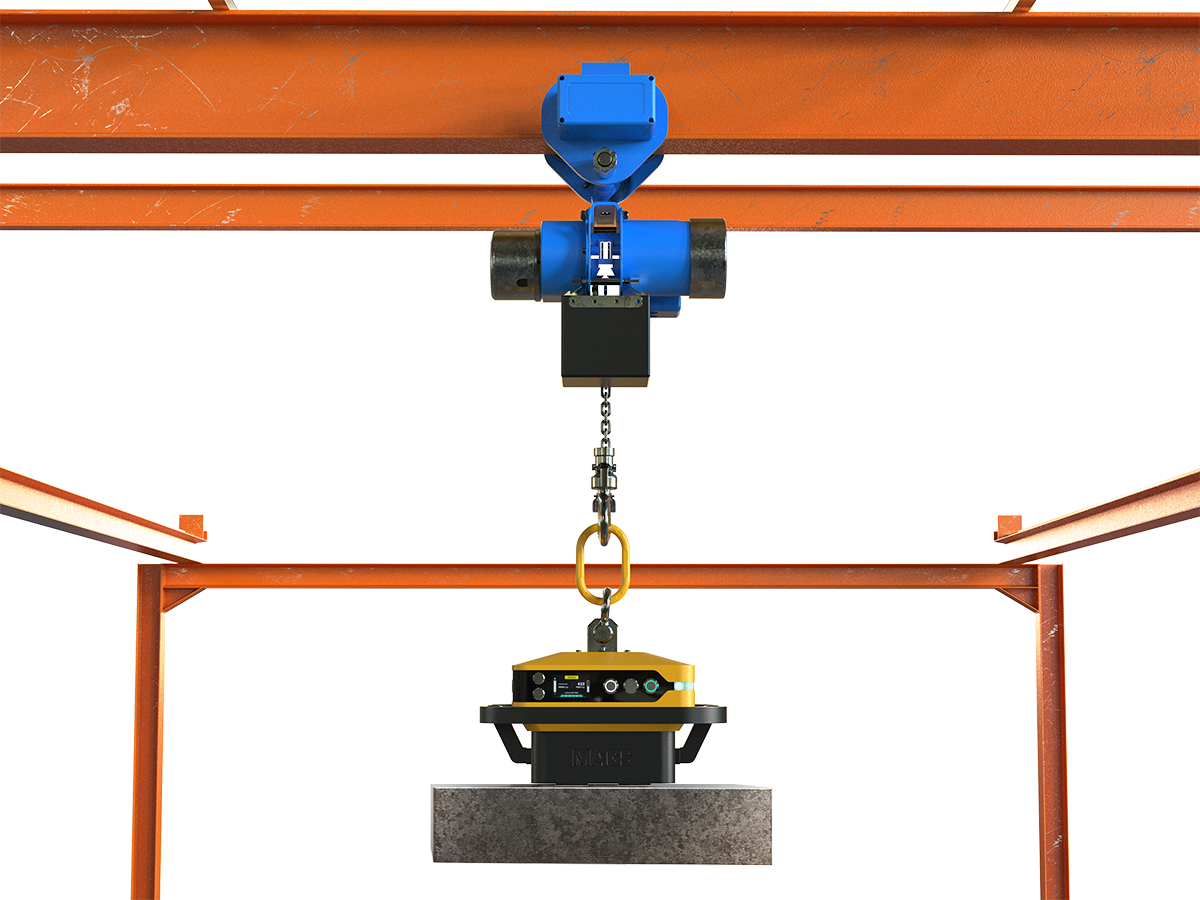

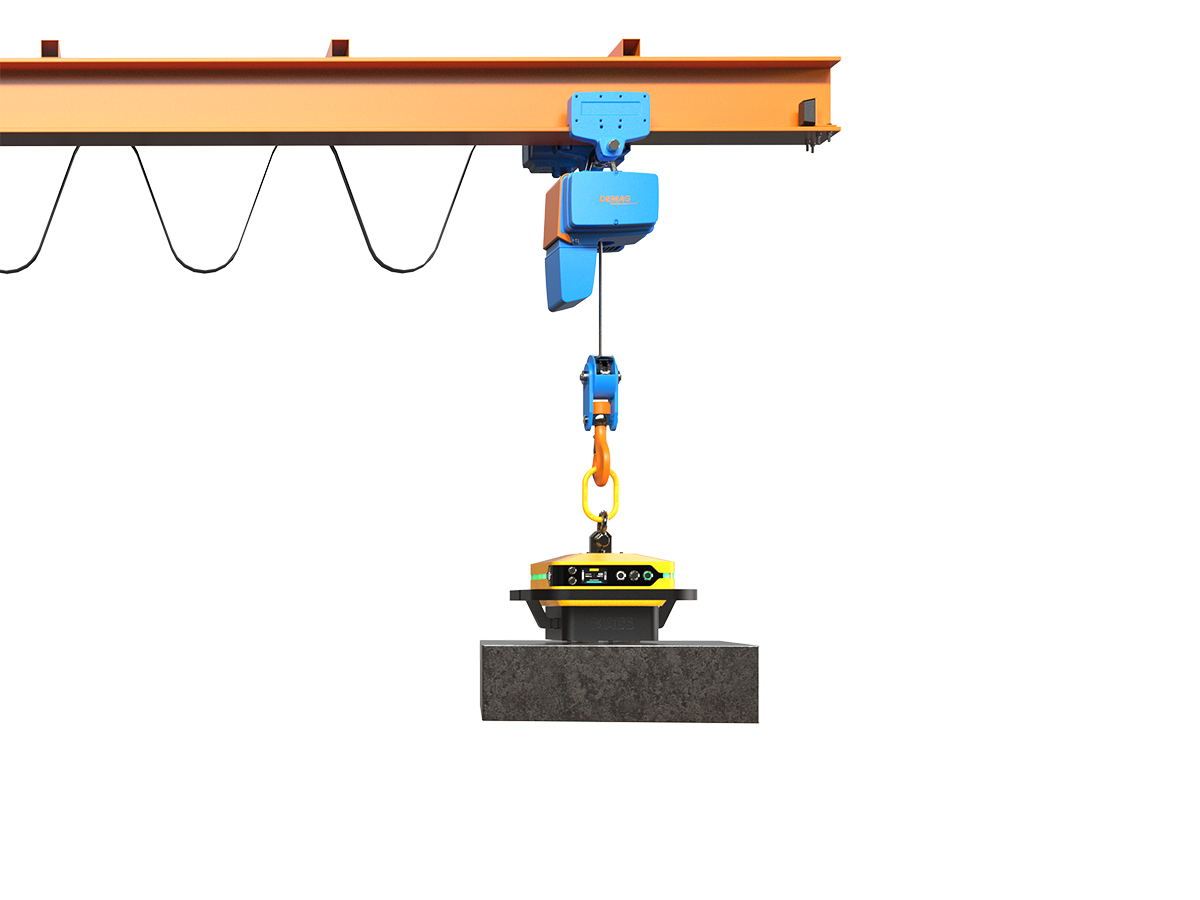

Independent of power supply sources, MAGS lifters can be moved to different production areas, even outdoors, and hooked up to jib cranes, overhead cranes, lifting beams, forklifts and other handling systems. The reduced overall dimensions allow them to work in tight spaces, even with complex shaped loads.

MAGS magnetic lifters are manufactured by AGS, a leading company in Automation & Robotics solutions.

Jib cranes

Forklifts

Lifting beams

Concentrated power

The permanent-electro technology combined with an alternating square pole system ensure maximum concentration of clamping power even with rough surface workpieces.

Electricity is only required for activation and deactivation, for few seconds.

Even when the batteries are discharged, the load is retained, in total safety.

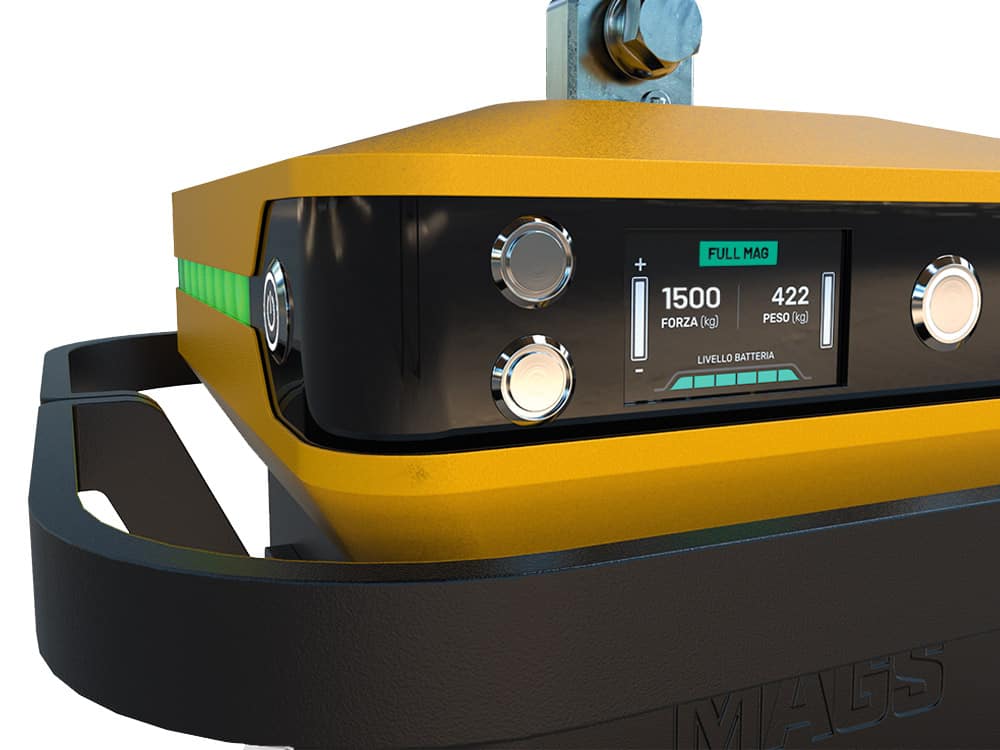

Industry 4.0 compliant

MAGS is designed for interconnection with the factory logistics system and can be interfaced with the crane or automated handling systems via the most common field buses: Modbus TCP/IP and Modbus RS-485.

The MAGS lifters’ internal memory records all operations: date, time, type of activity, force applied, load weight and alarm signals.

The data collected can be easily consulted afterwards, by connecting the lift via a common USB cable to a PC.

You can check the usage rate and keep track of any misuse.